Exclusive Features

- Sturdy and Robust

- Construction

- Consistent and Uniform Mixing

- Low Power Consumption

- Vibration / Noise free operation

- Ideal for Rubber and Plastic Material

- Force Feed Lubrication

- Safety Device against Overload

- Low Maintenance Costs

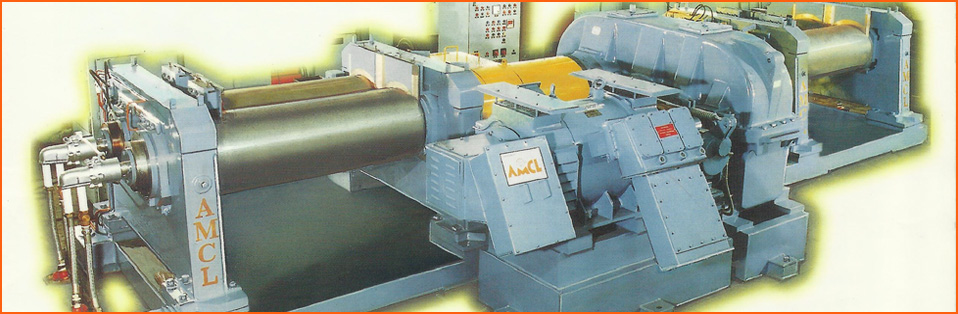

Mixing Mills

AMCL offers a wide range of two roll mills for processing rubber & plastic material in various sizes and applications, viz., mixing, cracking, sheeting, warming, feeding, compounding etc. The mills are sturdy and robust in construction and are offered with high degree of safety parameters.

Product Features

- The Uni-drive design 261x 84" mills are manufactured as per design by KOBE MACHINERY CO. LTD., Japan. With rich experience in the development and engineering of hi-tech tyre machinery, AMCL has developed various other sizes of mills in Uni-drive & bull gear design.

- The mills are manufactured with chilled cast iron cored rolls, plain / grooved.

- Frames & caps are of welded design / cast steel duly stress relieved and machined to accommodate roll journals & other mill accessories.

- Rigid base plate is suitably drilled to accommodate foundation bolts / vibromounts.

- Centralized force feed oil / grease lubrication system with separate piping & sight glass for each journal.

Safety Parameters

- Shear pad type mechanical safety device against overload.

- Interlock between lubrication system & mill drive pressure switch provided to ensure tripping the mill above / below set limit of oil pressure.

- Overhead wire / knee / belly bar arrangement for emergency stop.

- In uni-drive mill, the rear roll is directly coupled with output shaft of the gear reducer through a rigid gear coupling. This avoids conventional bull gear and pinion resulting in minimizing friction losses and power consumption.

The uni-drive mill also offers the following advantages:

- Reduced maintenance

- Vibration / noise free operation

- Less expensive foundation

- Saving on working space

- Easy to equip and remove

- Reduces roll inventory

Optional Features

- Plain /grooved, cored/drilled rolls

- Motorized nip adjustment assembly AC/DC motor & drive

- Pneumatic / Hydraulic operated guide

- Antifriction roller bearings

- Stock blender

- Roll speed and friction ratio to suit customer requirements.

- Vibromounts / foundation bolts

Standard Sizes

| 26" dia X 84" | |

| 22" dia X 60" | |

| 16" dia X 42" | |

| 22" X 25" Cracker mill | |

| 21" x 24" x 36" Refiner Mill | |

| Twin Mill | |

| Special sizes on request | |

Our Clients