Tube Curing Press

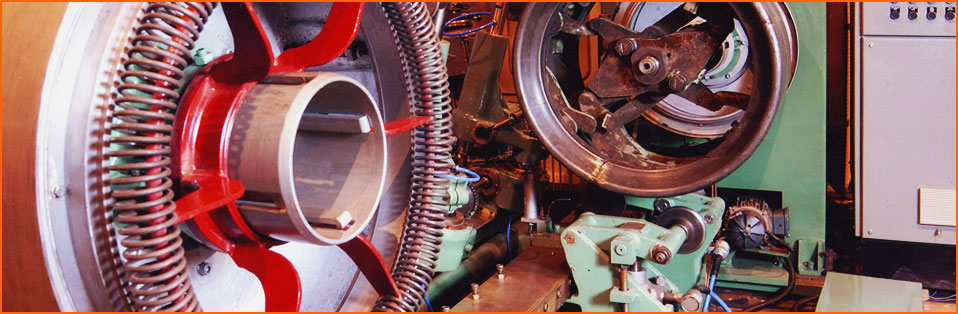

AMCL designs and manufactures a complete range of Tube Curing Presses for all vehicles from scooters to heavy trucks and OTR. Great flexibility is built in to these machines with each tube company's design preferences in mind with due emphasis on safety precautions and interlocks.

Tube Curing Press - Construction Features :

- Press frame with side shields

- Toggle lever mechanism

- Press table with insulating plates

- Mould height adjustment assembly with mould support plate

- Main drive motor with brake

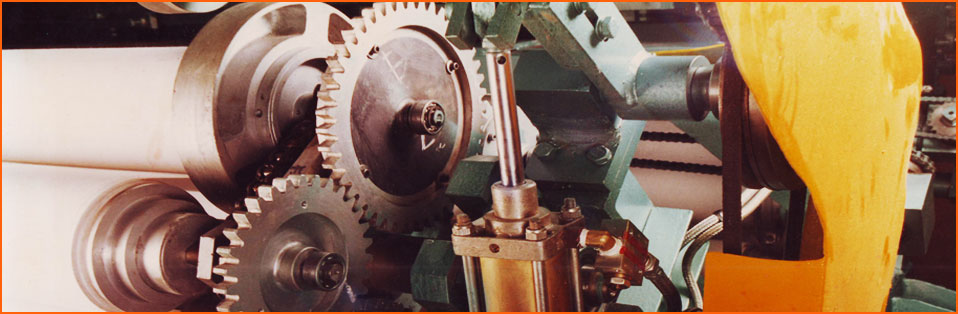

- Gearbox

- Safety bar assembly

- Centralized lubrication system

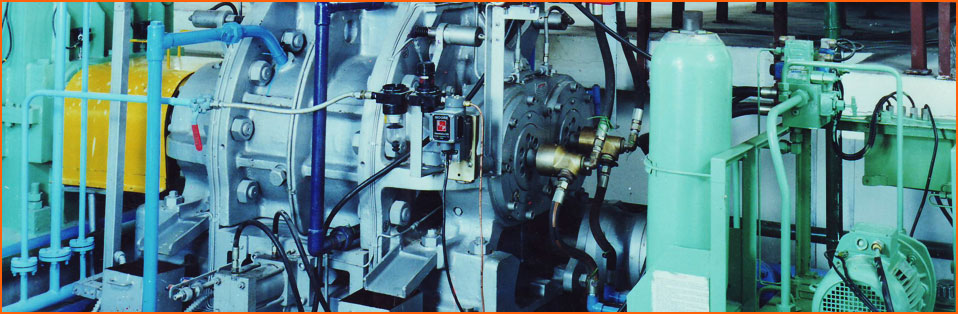

- Instrumentation and piping includes diaphragm valves

- Solenoid valves

- FRL unit

- Strainer

- Pressure switch

- Flexible hoses

- Timer/PLC for auto cycle control

- Control panel with lamps and push buttons etc.

Genernal Description

Design and Operation Features

Tube curing presses require a drive enabling the mould halves to close within the shortest possible time in order to avoid premature curing of non-vulcanized and relatively thin material in the hot mould and to launch the curing process under internal pressure as quickly as possible. Great importance, therefore, is given to the construction of the drive on tube curing presses. Even with the largest press of this model, the drive does not take more than 5.5 seconds to close the mould halves.

Another important feature is revealed by opening and closing movement of this press. In opening, the lower part of the press goes down by simultaneously tilting forward while the upper part remains fixed, thus providing a desk like loading and unloading position which is particularly advantageous in view of the flabby tubes having a relatively large diameter.

The presses are delivered with or without curing platen. However, in the case of larger tubes, mould with a steam jacket is generally used to obtain uniform curing. As the curing platen serves as mould fixation also, the upper curing platen is replaced by a special mould retaining plate in mould with a steam jacket, while the lower mould half is fixed to the table. A central adjustment installation on the upper part of the press enables quick and uniform adjustment to the various mould heights.

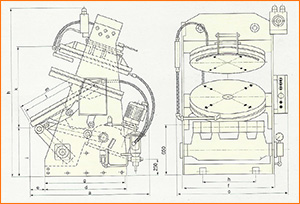

Basic Specifications

Technical Data |

Model No. | |||||

EKK-S |

EKM-s |

EKO-S |

EK1-S |

EK2-S |

||

For moulds to be inserted in |

Scooter tyre & industrial type sizes |

Motorcycle & passenger car tyre sizes |

Passenger car & light truck tyre sizes |

Truck tyre sizes |

Truck tyre & Tractor tyre sizes |

|

Maximum mould height without curing platens(mm) |

270 |

310 |

390 |

400 |

500 |

|

Minimum mould height without curing platens ( mm ) |

170 |

170 |

240 |

250 |

290 |

|

Maximum mould height with curing platens ( mm ) |

160 |

200 |

250 |

- |

- |

|

Minimum mould height with curing platens ( mm ) |

60 |

60 |

100 |

- |

- |

|

Weight in Kgs without curing platens |

1250 |

2200 |

2500 |

4200 |

9100 |

|

Closing Pressure in tons |

20 |

35 |

50 |

65 |

80 |

|

Closing time on seconds |

3 |

3.3 |

3.7 |

4.3 |

5.5 |

|

Main drive motor KW |

1.5 |

1.5 |

2.2 |

3.7 |

7.5 |

|

a |

1200 |

1370 |

1600 |

1700 |

2200 |

|

b |

1900 |

2000 |

2300 |

2300 |

2950 |

|

c |

1120 |

1370 |

1560 |

1800 |

2200 |

|

d |

900 |

1080 |

1010 |

1080 |

1580 |

|

e |

100 |

100 |

180 |

200 |

270 |

|

f |

820 |

1020 |

1170 |

1400 |

1710 |

|

g |

920 |

1030 |

960 |

1020 |

1505 |

|

h |

500 |

680 |

730 |

920 |

1250 |

|

i |

630 |

550 |

700 |

560 |

750 |

|

k |

650 |

700 |

1000 |

1250 |

1650 |

|

l |

650 |

810 |

980 |

|

|

|

m |

650 |

850 |

990 |

1200 |

1630 |

|

| Required Media | |||||

Internal curing |

Compressed Air or Steam |

||||

External curing |

Steam up to 16 atm |

||||

Control Air(Oil free) |

1.5 atm |

||||

Electric power |

220/450 Volts, 50 cycles |

||||

Shipping space in m3 |

3 |

3.6 |

5.5 |

7 |

13 |

Packing weight in kgs |

300 |

350 |

400 |

450 |

600 |

Optional items - Tube Mould

Making its range complete, AMCL also manufactures the inner tube making machinery to customer's requirements which include

- Mixing mills 16" x 42" , 22" x 60" size

- Extruder with AC/DC drive in size 4.5", 6", 8" etc.

- Tube splicer as per design from MIDLAND TYRE MACHINERY CO., UK.

- Tube cooling line as per design from MIDLAND TYRE MACHINERY CO., UK.

Clients