Tube Splicer

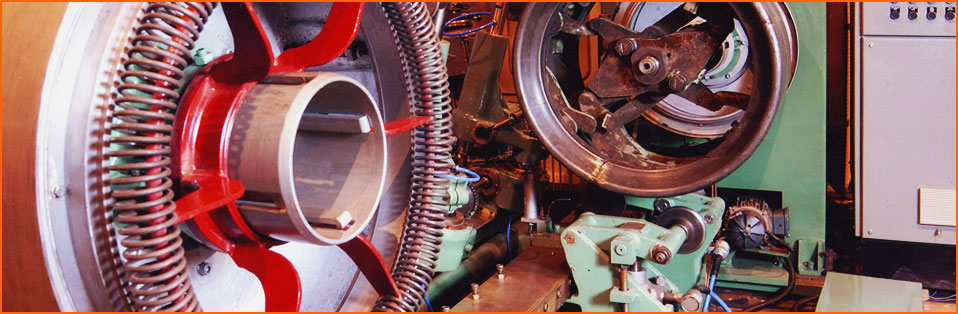

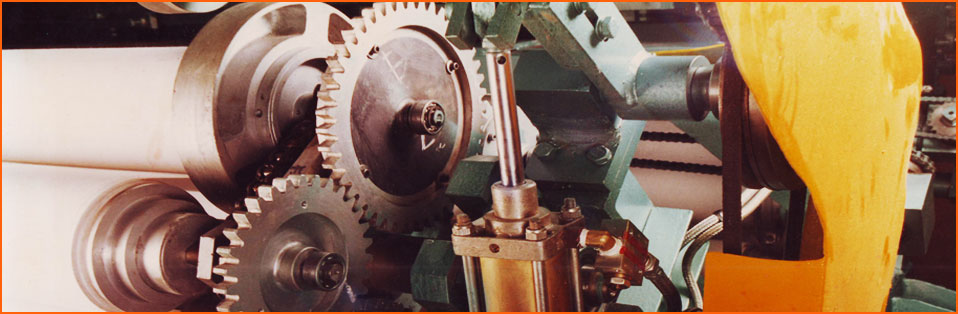

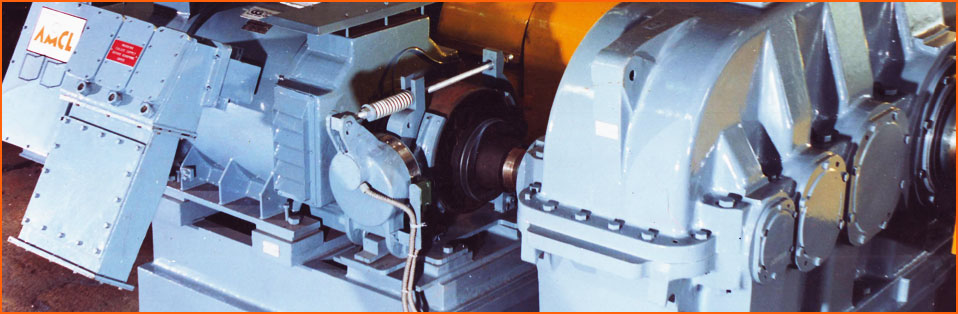

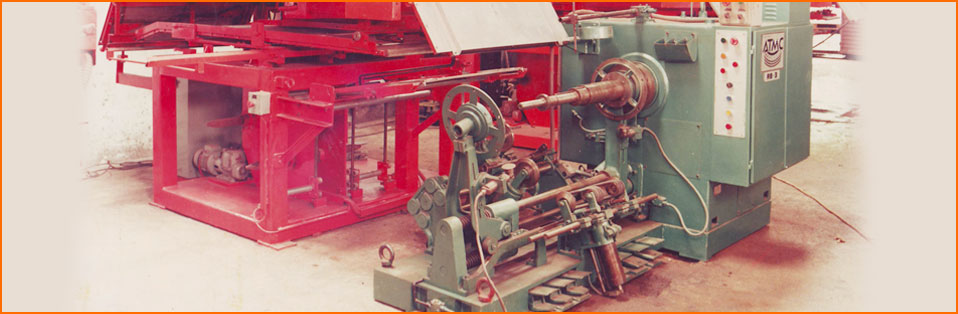

Inner Tube Splicing Machines:

The Inner Tube Splicing Machines are the mainstay in tube manufacturing plants. Their reliability is important to ensure consistent high strength tube joints and tubes durability.

AMCL - MIDLAND's comprehensive range of Tube Splicing Machines are acclaimed as the most advanced systems and provide the end user with a range of advantages. Their Microprocessor based Control System simplifies the complex sequences into simple and straightforward tasks for the operator.

AMCL - MIDLAND'S Tube Splicers are enhanced with advanced features such as:

• Dropping knife blades Precision knife guidance systems

• State-of-the-art knife heat control

• Solid state electrical control. Other special features such as hydraulic adjustment of tube width, simple knife cleaning facility, gravity scrap collection and swash-type hydraulic pump ensure the product's leadership in Splicer technology.

The standard AMCL - MIDLAND range of Inner Tube Splicing machines will join butyl and natural rubber or natural rubber and SBR blends, from bicycle to heavy off-the-road tubes. The machines are also suitable for the production of heat curing bags.

Model |

900 |

1100 |

1200 |

|

Tube Flat Width Maximum |

200 mm |

500 mm |

750 mm |

|

Flat Width Minimum |

20 mm |

120 mm |

450 mm |

|

Double Thickness |

20 mm max |

20 mm max |

20 mm max. |

|

Minimum Unspliced Tube Length |

800 mm |

800 mm |

1200 mm |

|

Machine Height(Approx.) |

1900 mm |

1900 mm |

2300 mm |

|

Machine Width(Approx.) |

1600 mm |

1600 mm |

2100 mm |

|

Machine Depth(Approx.) |

1600 mm |

11600 mm |

1700 mm |

|

Nett Weight (Approx.) |

2500 Kgs |

2500 Kgs |

5000 Kgs |

|

Tubes Per Cycle |

Two |

One |

One |

|

Approximate Machine Cycle Time |

25-40 Seconds |

25-35 Seconds |

35-55 Seconds |

|

Electric Supply |

6.5 KW at 415V, 3 Phase, 50 Hertz |

|||

Operation Sequence

- Heated knives are positioned just below the tube fold entry position.

- Immediately the tube is clamped and the knives rise automatically to commence horizontal movement, cutting the tube along its width. This ensures cuffing operation without any delay.

- The knives travel in 'creep' speed at the tube fold knife entry and exit points. This ensures free movement of the knives during tube cutting operation preventing the possible damage or distortion of the tube faces.

- Once the knives have cleared the entry fold area at creep speed, they automatically change to "slow" speed and cut the main body of the tube. Both the "creep' and "slow" speeds are fully adjustable.

- On completion of tube cutting operation, the knives immediately drop to enable splicing of cut edges using hydraulic pressure thus minimizing operation cycle time and maximizing productivity.

Clients