Curex - B Tyre Curing Press

Resulting from its ongoing endeavor to produce high value added products and diversify its business, AMCL in collaboration with world leaders KOBE STEEL, LTD., Japan, brings to India advanced technology to manufacture the most rugged and efficient Tyre Curing Presses. Its state-of-the-art manufacturing facility at Butibori is equipped with latest machinery in a covered area of over 5,000 sq. m. The company's personnel are highly qualified, trained and motivated to practice its corporate philosophy which gives utmost importance to customer satisfaction through value added quality products and services. CUREX - B Tyre Curing Presses work in the most demanding conditions with high quality and efficiency, ensuring trouble free production of tyres.

Excellence with proven performance

The CUREX - B Tyre Curing Presses are a result of extensive R&D, proven design and rugged construction that assure years of reliable operation with minimum maintenance. The equipment automatically loads cures and unloads high quality radial and bias tyres. .

Enhanced productivity

The entire operation of 9 green tyre loading alignment curing stripping and tyre unloading is done with precision in short time eliminating the dangers of loader misalignment and improper curing, resulting in enhanced productivity.

Versatile for specific design needs

The tyre and mould design, curing specifications etc., are unique to each individual tyre manufacturer. Considering these specific needs the CUREX-B Tyre Curing Presses offer great versatility in design, adapting to suit most of the segmented and two piece moulds used for production of the entire range of tyres.

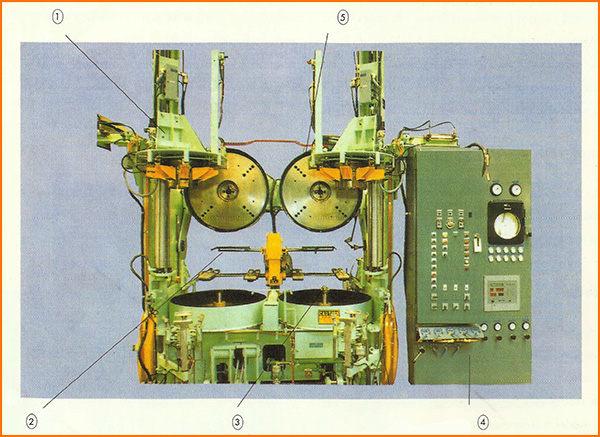

Press Configuration

The CUREX-B Tyre Curing Presses for all types of tyres

1. Vertical Loader

The Vertical Loader is a high precision device of adjustable size, which loads and aligns the green tyre in the press mould.

2 .Unloader

The unloading device is manufactured in two options

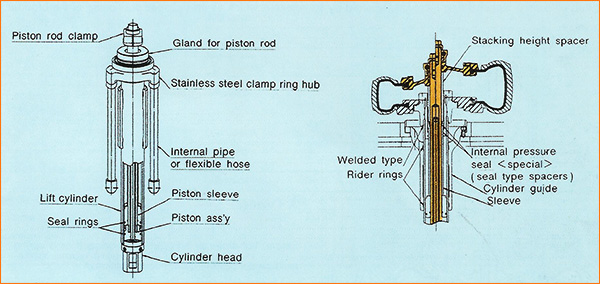

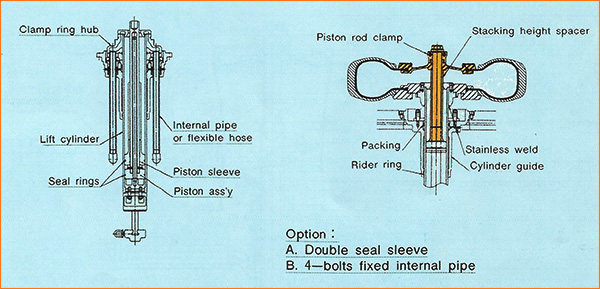

3. Bladder Control Mechanism

The bladder control mechanism is of dual purpose design, suitable for tyres of all sizes which facilitates

4. Control Panel

The control panel is the process operations control device laid out, designed and custom built to specifications of the customer.

5. Mould Heater

Mould heating can be achieved by using platen heater or dome heater in single or double cavities depending on the size of the press.

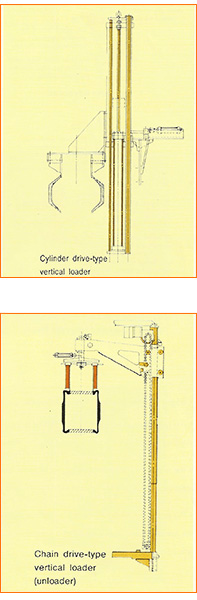

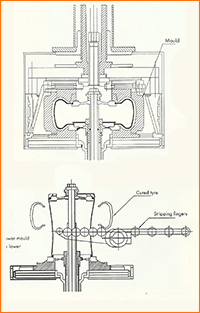

Vertical Loader

- The green tyre is first secured in the vertical loader by the radial motion of the tyre holding fingers ( by air cylinder actuation ), then lifted and placed into the mould cavity.

- For passenger car and some truck lyre CUREX presses, the green tyres are initially positioned on the front tyre holders situated at each of the moulds.

- For bus and truck tyres the green tyres are lifted directly from the floor level conveyor and placed into the mould.

- Passenger car, bus, truck tyre presses are equipped with independent rear unloaders.

- The cured tyre is stripped by an independent device. This reduces the possibility of loader misalignment.

- Smooth and precise "swing" of the loader is ensured by a Geneva mechanism which is pneumatically or hydraulically actuated.

- Vertical movement of the loader is achieved by

- Pneumatic cylinder drive for passenger car tyres

- Chain drive for truck/bus tyres and

- Accurate concentricity of the green tyre vertical loader with respect to the mould is ensured by the centering guide.

The CUREX - B presses are supplied with a high accuracy, Vertical Chuck Loader. It is a crucial and value added design feature to the press. It loads the green tyre into the mould with great accuracy, resulting in a tyre finish of high quality.

Unloaders

Bucket Type Unloader

-

The action of the bucket type unloader of CUREX-B press is similar to that of a hydraulic excavator bucket.

- The lower roller table fingers support the tyre while the bladder is being extracted and then tilt to allow the tyre to roll - off the unloader.

- Bucket type unloaders are used with twin mould CUREX - B presses and its actuation is by a single hydraulic (water) cylinder.

- . The bucket type unloader is ideally suited for unloading the passenger car and light truck tyres off the press.

- This type of unloader provides pure vertical motion for stripping the cured tyre from the upper bladder clamp.

- The stripping is made possible by two hydraulic (water) cylinders operating in conjunction with a cam - plate.

- This mechanism eliminates the risk of interference between the tyre bead and upper bladder clamp ring during unloading operations.

Bladder Control Mechanism

The bladder control mechanism of the CUREX - B press has an adjustable stacking height to position the bladder for curing pre-formed (radial) tyres and undercut drum built tyres. It locates top clamp ring with upper tyre bead to assure tyre uniformity and positive bladder centering.

Bladder Control Mechanism For Platen Type

Bladder Control Mechanism For Dome Type

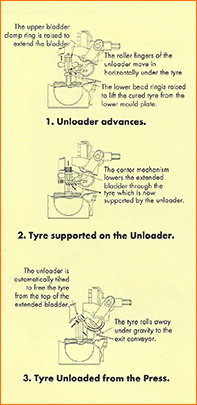

Sequence of Operation

1. Loading and Centering: The green tyre is loaded into the mould with the bladder fully extended. The rigid center post ensures that the bladder remains precisely centered in the green tyre for all subsequent operations.

2. Shaping: The bladder is tightly secured in the upper and lower clamp rings of the bladder control mechanism, simultaneous action of tapered actuating ring and downward movement of the upper clamp ring provide the tyre with toroid shape. The shaping medium is lowered to a height determined by the spacers, which assures proper positioning of the bladder in the tyre for optimum tyre uniformity.

3. Curing: Steam, hot water or nitrogen is introduced as a curing medium as per the curing specifications.

4. Stripping: The curing lyre is stripped from the lower mould with bladder extended, by raising the lower bead ring.

Technical Data

Specifications for tyre Curing Presses

Tyre type |

Passenger | Truck /Bus |

||||

Model |

A350-45 M 11 | A65055M14A | A 1000 – 65 1/2 MRI |

|||

Type of Mould Heating |

Platen | Dome | Dome | |||

Max.closing Force/Mould |

103 Kg |

160 |

295 |

453 |

||

Shield Inner Diameter |

mm |

1118 |

1310 |

1575 |

||

Mould Thickness |

Minimum |

mm |

203 |

241 |

254 |

|

mm |

457 |

445 |

635 |

|||

Bead Dimater |

Minimum |

mm |

304.80 |

381 |

304.80 |

|

mm |

406.40 |

571.50 |

622.30 |

|||

Gree Tyre Height |

Minimum |

mm |

178 |

- |

- |

|

mm |

864 |

762 |

1143 |

|||

Typical Max.Tyre Size |

Bias |

|

8-16 |

12.00-20 |

13.00 - 24 |

|

Radial |

|

9.15 R 15 |

9.00 R 20 |

11.0 R 20 |

||

Max. Steam Pressure for Platen/Dome |

Kg/cm2 |

10.5 |

7 |

7 |

||

Type of unloader |

Bucket |

Right Angle Motion |

||||

Typical Vertical Loader Model |

|

A55 L 11 K |

A 65 ½ L 1 |

|||

Specifications for Post Cure Inflator

Tyre type |

Passenger |

Truck/Bus |

|||

Model |

A45 P 18K |

A55 P 2K |

A 65 ½ PKI |

||

Bead Diameter |

Minimum

Maximum |

mm |

304.80 |

406.40 |

406.40 |

mm |

406.40 |

571.50 |

609.60 |

||

Tyre outer Diameter |

Minimum

Maximum |

mm |

445 |

780 |

910 |

mm |

981 |

1154 |

1385 |

||

Maximum Tyre width |

|

mm |

406 |

330 |

445 |

Set Bead Width |

Minimum

Maximum |

mm |

102 |

76 |

178 |

mm |

203 |

250 |

286 |

||

Inflator Air Pressure |

Kg/cm2 |

7 |

10.5 |

14 |

|

Number of position |

4 |

4 |

4 |

||

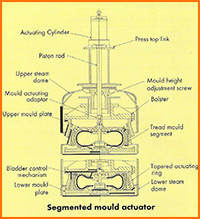

Segmented Mould Actuation

The entire range of CUREX - B curing presses have provision for the use of segmented mould and its actuation system.

Working

- Once the green tyre is loaded, the mould actuation cylinder advances the upper bolster and upper mould plate towards the green tyre and lower mould plates.

- Simultaneously, the tapered actuating ring advances the tread segments radially around the tyre.

- The combined action of this actuation system with the bladder control mechanism ensures precise centering between the mould, tyre and bladder. It also facilitates easy stripping of the cured tyre from the mould.

Post Cure Inflators

For Passenger and Light truck tyres.

CUREX - B press compatible automatic post cure inflators prevent the deformation of particular cords in cured tyres. Each inflator accommodates four tyres and is installed behind the curing press.

- The bayonet locking of the bead rings ensure that the tyre bead concentricity is accurately maintained. Individual pressure alarms for each tyre position can be provided.

- The inflator models are provided with gravity - operated roller

For Truck / Bus Tyres

- • The complete range of automatic post cure inflators for truck / bus tyres are also designed and manufactured. Each PCI model is designed to be linked to its press by gravity - operated roller conveyors and the specifications are similar to the gravity operated passenger car / light truck tyre models. The PCI can handle maximum inflation pressure of 14 Kg/cm2 (200psi).

Our Clients